A successful near-net-shape investment casting takes more than a

blueprint/drawing.

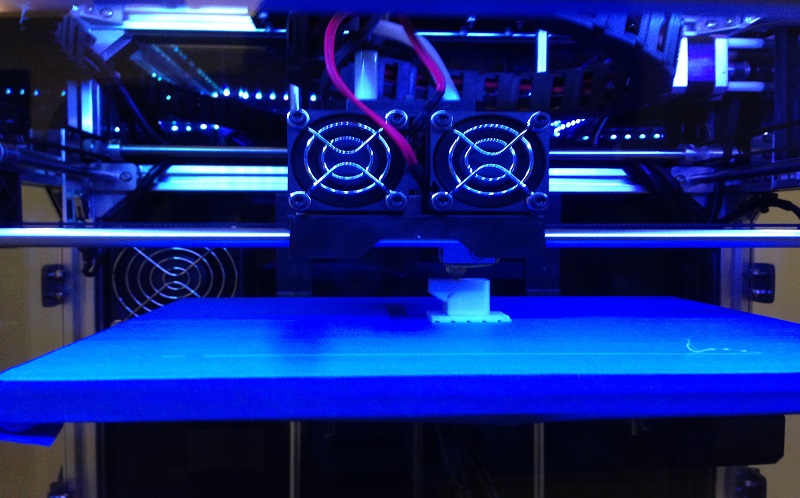

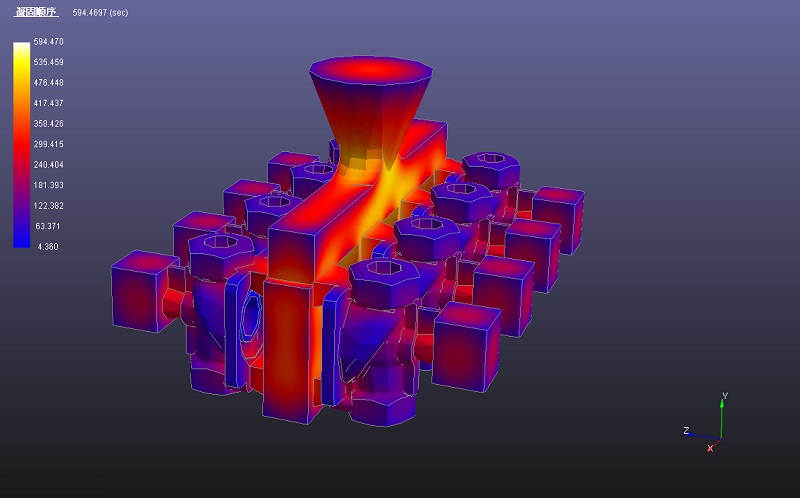

A computer modeling is utilized by MAX AND MONA for rapid

prototyping, casting process simulation, solidification modeling and continuous

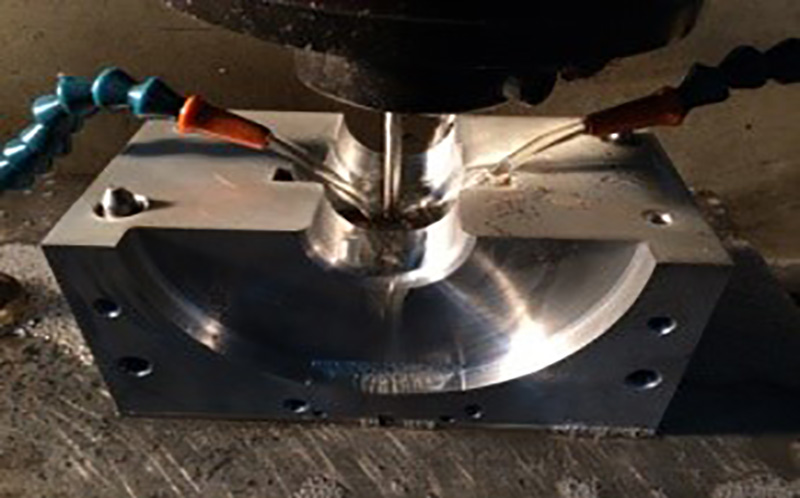

improvements. For tool-making MAX AND MONA's CAD/CAM with advanced CNC

machining center, EDM, grinding machine and wire cutting machines permit 4-axis

die cutting of complex parts, thus reducing the time and cost of single and

multiple cavity die construction.

MAX AND MONA also enjoy great reputation in CNC machining of

stainless steel, such as turning, milling, drilling, tapping. We are not the

largest but we are the best in stainless steel casting and machining. All the

facilities enable us to offer global customers cost-effective solutions and

competitive edge.

MAX AND MONA is the One-Stop-Solution for your regular demand and

“Mission Impossible”.

Our tooling and casting machine shop places a special emphasis on

inspection.